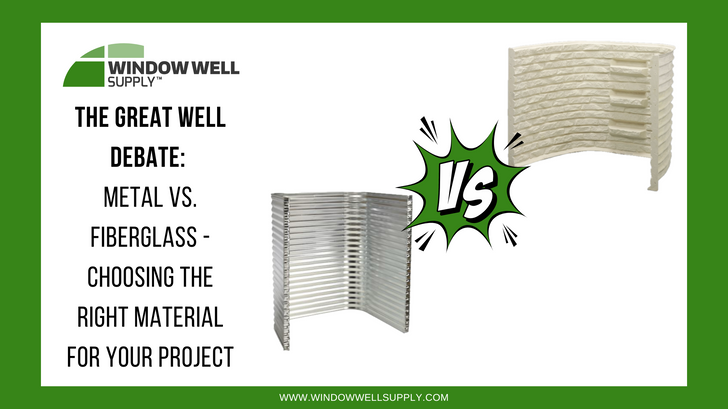

When it comes to well construction, two primary materials dominate the landscape: metal and fiberglass. Both offer distinct advantages and disadvantages, making the choice dependent on your specific needs and priorities. Let's delve into the pros and cons of each material to help you decide which well is right for your project.

Metal Wells: Strength and Tradition

Metal wells have been a trusted choice for generations, known for their:

- Unmatched Durability: Metal, typically galvanized steel, is incredibly strong and resistant to physical impact and harsh weather conditions.

- Fire Resistance: Metal offers excellent fire resistance, a crucial factor for some well applications.

- Versatility: Metal wells can be custom-fabricated to fit unique well casing sizes and depths.

However, metal wells also come with some drawbacks:

- Susceptible to Corrosion: Over time, metal wells can rust, especially in areas with high moisture or acidic soil. Regular maintenance is necessary to prevent leaks and maintain structural integrity.

- Heavyweight Installation: Metal wells are heavy, making transportation and installation more challenging. Professional installation might be required.

- Cost Considerations: Metal wells can be a more expensive option compared to fiberglass, particularly for larger well diameters.

Fiberglass Wells: Lightweight Champion

Fiberglass wells have emerged as a popular alternative, offering several advantages:

- Corrosion Resistance: Fiberglass is naturally resistant to rust and corrosion, making them ideal for areas with high moisture or acidic soil conditions.

- Lightweight Champion: Fiberglass is significantly lighter than metal, making them easier to transport and install, potentially saving on labor costs.

- Smooth Interior: The smooth interior surface of fiberglass wells reduces the risk of sediment buildup and simplifies cleaning.

While fiberglass offers compelling benefits, keep these considerations in mind:

- Susceptibility to Impact: Fiberglass can be susceptible to cracking or punctures if struck by a heavy object. Careful handling is crucial during installation and maintenance.

- Limited Size Options: Fiberglass wells are typically available in pre-fabricated sizes, which might not always accommodate specific well casing dimensions.

- Fire Considerations: While some fiberglass well casings are fire-retardant, they generally don't offer the same level of fire resistance as metal.

The Final Verdict: It Depends

So, which material reigns supreme? The answer depends on your specific project requirements:

- Prioritize Strength and Fire Resistance? Metal is the way to go.

- Value Lightweight Installation and Corrosion Resistance? Fiberglass might be your champion.

Considering Cost? Fiberglass may be a more budget-friendly option for smaller well diameters

Beyond Material:

Remember, well construction involves more than just the casing material. Factors like well depth, water table conditions, and local regulations all play a role in choosing the right well system. Consulting with a licensed well driller is crucial to ensure a safe and functional well for your needs.

Window Well Supply: Your Partner in Well Solutions

Whether you're considering a new well or need maintenance services for your existing well, Window Well Supply can be your trusted partner. We offer a variety of well-related products and resources to help you make informed decisions. Contact us today!

Lifetime Warranty On All WWS Covers

Lifetime Warranty On All WWS Covers

Free Shipping On All Products

Free Shipping On All Products

(262) 633-3707

(262) 633-3707

info@windowwellsupply.com

info@windowwellsupply.com